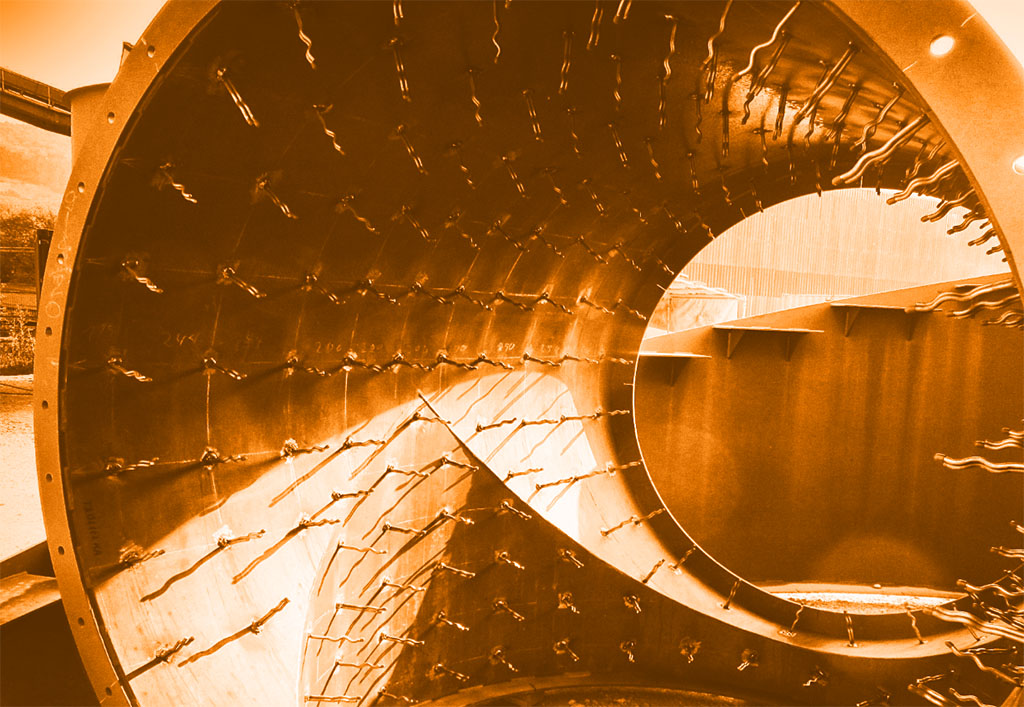

SZEROKI ZAKRES

DZIAŁALNOŚCI

W BRANŻY

OGNIOTRWAŁEJ

Sprawdź w jakich obszarach możemy nawiązać owocną współpracę. Do każdego klienta podchodzimy indywidualnie aby zaproponować optymalnie najlepsze rozwiązania.

- Piece przepychowe

- Piece z wysuwnym trzonem

- Piece samotokowe

- Piece z obrotowym trzonem

- Piece do obróbki cieplnej metali nieżelaznych

- Piece do topienia aluminium

- Kadzie odlewnicze w przemyśle stalowym

- Kadzie odlewnicze w przemyśle metali nieżelaznych

- Kotły parowe węglowe z paleniskiem rusztowym

- Kotły parowe fluidalne

- Kotły pyłowe

- Rurosuszarki

- Kotły wodne

- Wyłożenia ogniotrwałe palników

- Kotły na biomasę

- Montaż kompletnych linii do produkcji cementu

- Remonty wymienników ciepła

- Piece obrotowe

- Kalcynatory

- Chłodniki

- Rurociągi 3-go powietrza

- Piece Maerza

- Piece szybowe

- Kotły rusztowe w spalarniach odpadów komunalnych

- Piece obrotowe w spalarniach odpadów specjalnych

- Piece fluidyzacyjne w oczyszczalniach ścieków

- Suszarnie

- Kotły odzyskowe

- Kotły na biomasę

- Piece tunelowe do wypału materiałów budowlanych

- Kotły do produkcji gipsu

- Komory spalania w ciągu technologicznym produkcji materiałów budowlanych

REALIZACJE

W KRAJU

I NA ŚWIECIE

Jako duża międzynarodowa firma realizujemy zlecenia w całej Europie oraz poza jej granicami. Mamy wielu stałych, zadowolonych Klientów a każdego roku realizujemy więcej zleceń z większą liczbą kontrahentów.

POGOTOWIE OGNIOTRWAŁE

Specjalna linia czynna całą dobę

ZGŁOŚ INTERWENCJĘ

Wychodząc naprzeciw oczekiwaniom naszych Klientów uruchomiliśmy specjalną linię pogotowia ogniotrwałego czynną całą dobę:

Jesteśmy pierwszą firmą z naszej branży, która posiada takie rozwiązanie.

Dzięki infolinii jesteśmy w stanie szybciej przygotować nasz zespół remontowy i opracować plan działania dostosowany do zaistniałej sytuacji.